Engineering

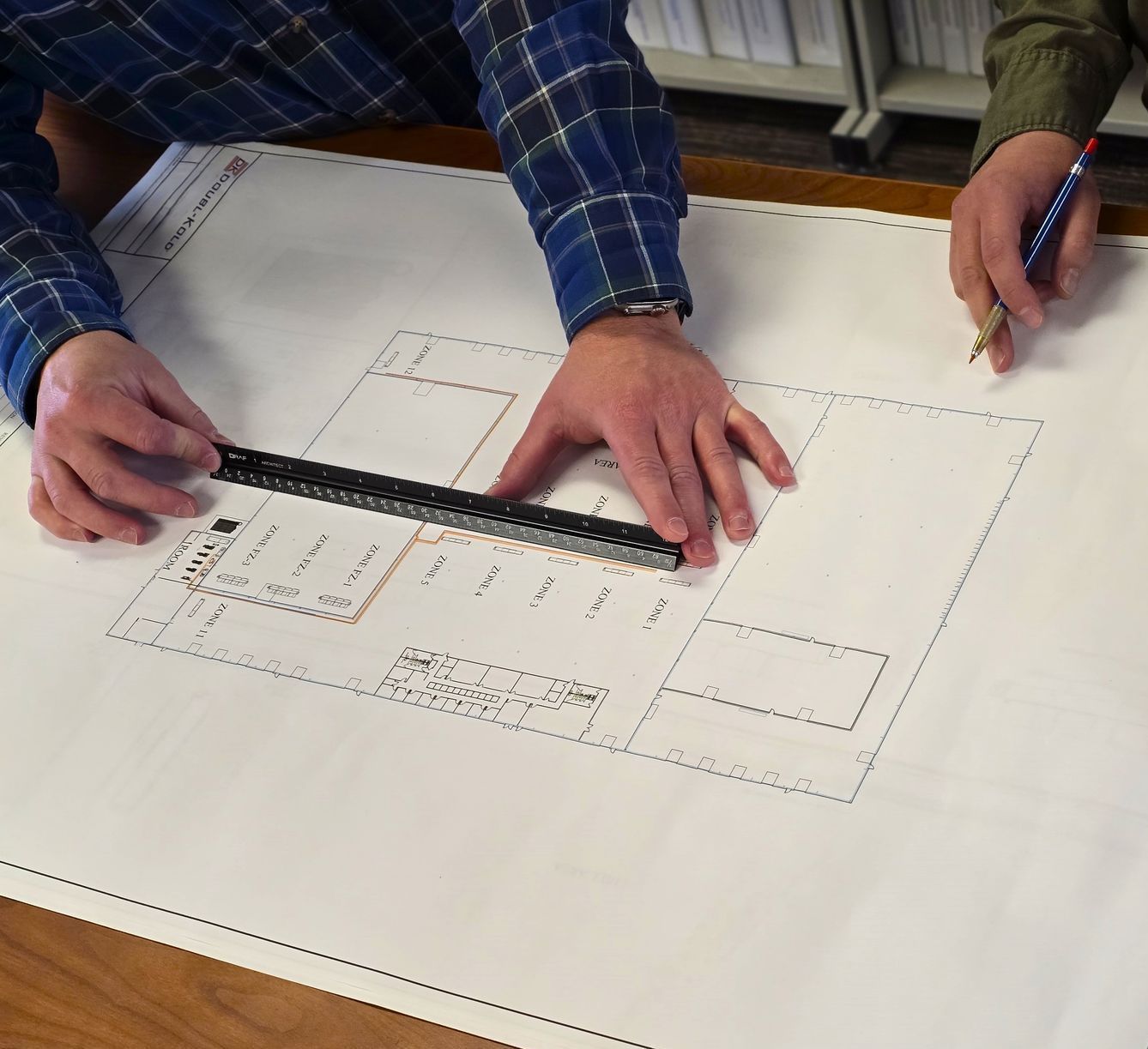

We have three professional engineers on staff, available to provide an extensive array of services including assisting in compliance with PSM/RMP regulatory requirements and project engineering/design. Our engineers are constantly traveling to job sites for mechanical integrity checks and safety management.

Our History of Engineering

Doubl-Kold is proud to have an established engineering department since 1999. With multiple projects spanning farther than the United States to serve the industrial refrigeration industry.

Our engineers have assisted in dozens of designs for construction projects as well as remodeling and retrofitting. We strive to have the most efficient and user-friendly systems to give our customers the best opportunity to grow their company. Our engineers have the capability to visit our customers to physically assess and measure the systems for more precise support in our projects.

Throughout the years, Doubl-Kold’s engineering department has hosted several Ammonia Emergency classes. In efforts to educate the community working with ammonia and ammonia emergency incidents, we provide annual refreshers on Ammonia Awareness and 24-hour Hazmat Technician courses. Courses provided by Doubl-Kold meet OSHA 29 CFR 1910.120 (q) requirements.

Having the opportunity to educate our community and fellow members in the industrial refrigeration industry allows us to expand our knowledge and understanding of the food packing and storage phenomenon. The laws and regulations within our industry are constantly being adjusted and added to so our engineers take the time to be part of the conversations and stay ahead of the fluctuating requirements.

Our Engineering Services

- PHA – Process Hazard Analysis

- RMP registrations and submissions

- 3-year Compliance audit (required by PSM and RMP)

- 5-year MI – Mechanical integrity inspection and testing (required by PSM and RMP)

- Annual IIAR safety inspections and safety testing

- Ultrasonic pipe & pressure vessel testing – NDT

- Update PSI – Process Safety Information

- MOC – Management of Change and PSSR – Pre-Start Safety Review

- Development of standard operating procedures

- Development of maintenance procedures

- Energy Balance (load) and ammonia charge calculations

- Pressure relief system calculations and design

- Engine room ventilation system calculations

- Pipe labeling & valve tagging

- Creation and updates of piping and instrumentation diagrams (P&ID’s)

David Champoux, P.E.

Licensed since 2014

David served his engineering internship with Doubl-Kold while studying at Gonzaga University and has been on our team for 16 years. Working in engineering design and construction for ammonia and assisting in PSM programs. David is licensed in Washington, Oregon, and Alaska.

Kem Russell, P.E.

Licensed since 1989

Kem, University of Washington alumni, has worked for Doubl-Kold for 25 years in the engineering department. He specializes in engineering and construction for ammonia and “Freon”, as well as medium and low temp industrial refrigeration systems. He also designs storage, process cooling, blast freezing, pressurized cooling and ripening systems, energy analysis, complete system design including controls, and PSM/RMP adherence. Kem is licensed in Washington state.

Michael Millet, P.E.

Licensed since 2019

After graduating from Brigham Young University, Michael has worked for Doubl-Kold for the last 11 years in the engineering department. Specializing in engineering design and construction for ammonia and assisting in PSM, ARM and RMP programs. Michael is licensed in Washington and Oregon.